The topics covered on this site include activities in which there exists the potential for serious injury or death.

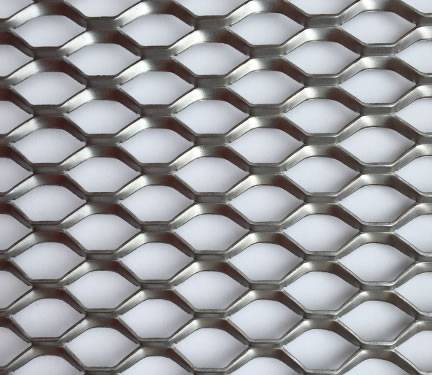

Nailing pattern for metal lath. Appropriately the measure of an expanded metal lath product s quality begins during the manufacturing process. Clearances to flue vents. And astm c1063 standard specification for installation of lathing and furring to receive interior and exterior portland cement based plaster. Lath fasteners to concrete.

First let s deal with the proper lapping of metal lath. The large number of openings provide for a better stucco bonding. Use 3 8 diameter shank 3 4 in length. What do you use for fastening metal lath i m curious as to what you use for fastening metal lath for scratchcoat warning.

You can use it for your entire project if your building dept. Self furring lath dimples v grooved or ribbed lath meets these furring requirements. Use this 27 in. 2 verify that no required under floor or attic vents are covered.

Basically if you. Nailing methods on horizontal applications all nails shall be driven flush with base driven home. They shall be provided with a loop or other preinstalled means for attachment. Can be used as a plaster base and reinforcement on almost all types of walls and ceilings and over wood or steel framing.

1 check at final for nailing pattern correct fastener type method of install and. Attachments for securing metal lath directly to concrete shall be attached with preinstalled wire of 0 068 diameter 14 ga. On vertical applications nails shall be bent over to engage at least 3 strands over and through rib on rib lath and bridge ribs with staples. Lath shall be furred away from vertical supports or solid sur faces at least.

For those who are uninitiated in the world of fasteners a nailing pattern or fastener schedule is the national state or regional building code allowances for fastening specific materials. This particular lath has a much smaller pattern in the wire itself. Manufacturing to astm specifications. Then minimum 2 5 self furring lath is installed over sheathing or solid surface the maximum spacing of supports may be 24 on center.

For direct attachment of lath to concrete surfaces the following method is also employed. There are hundreds of different nailing patterns for tons of building materials ranging from drywall to trusses and everything in between. Astm c 1063 requires that expanded metal lath be lapped a minimum of 1 2 inch along the long dimension of the sheet and a minimum of 1 inch along the end of the sheet. It allows the cement to bond to it very well and is usually used for patches transitions and uneven surfaces.

Steel lath for both interior and exterior projects if you require an easily cut material that can conform to curved surfaces.